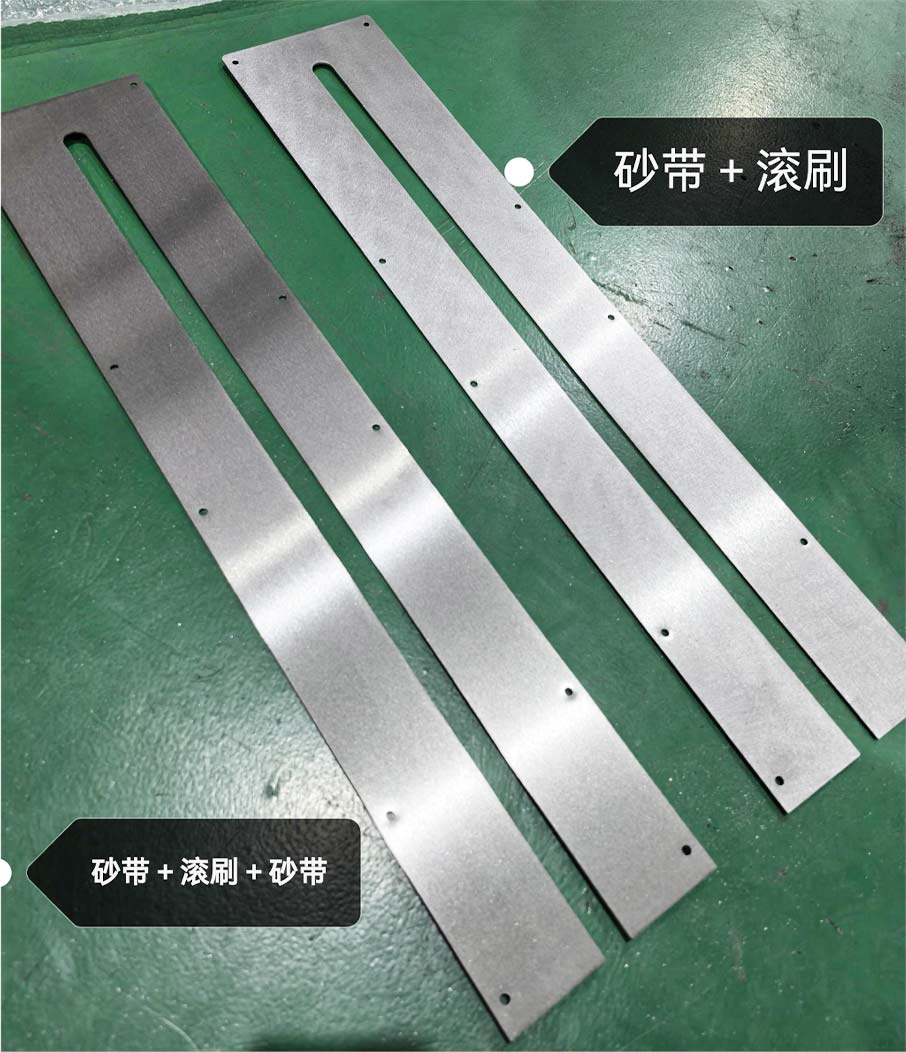

In the processing of stainless steel components, deburring and chamfering are crucial procedures to ensure product quality, enhance operational safety, and improve aesthetic appeal. Today, conducted sampling tests on stainless steel components provided by a client using machines with different station configurations. The aim is to present an intuitive comparison of processing results, enabling a clear understanding of the functions of different stations and the value of adding an extra station, thereby providing a solid reference for selecting the optimal station configuration based on actual requirements.

I. Basic Information of Sampling Tests

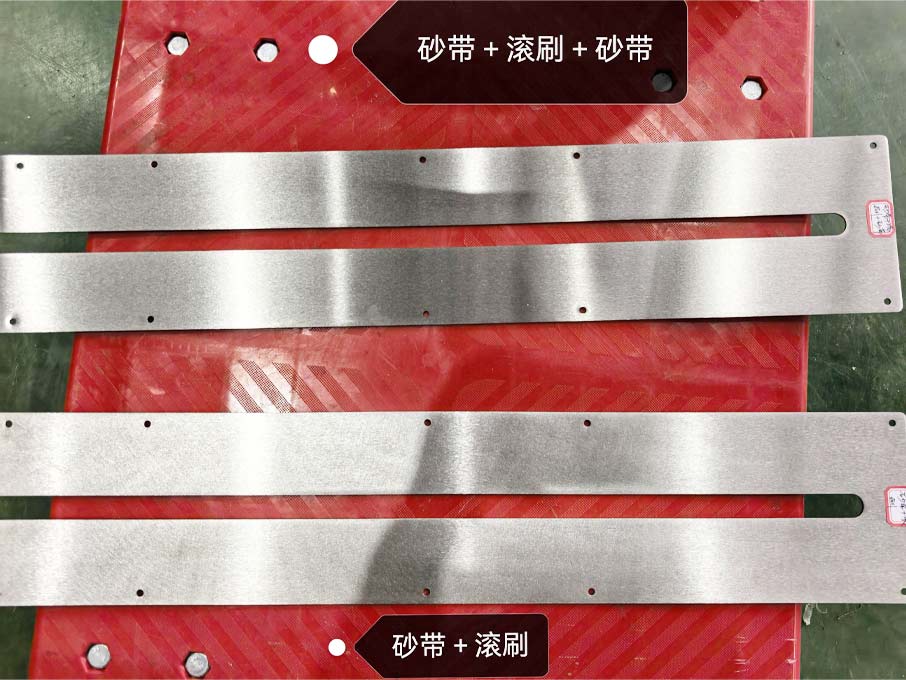

The processing objects of this sampling test were stainless steel components supplied by the client, with the primary objectives of removing burrs from the surfaces and edges of the components and performing chamfering. Two types of machines were used for testing: a 2-station deburring machine (abrasive belt + roller brush) and a 3-station deburring machine (abrasive belt + roller brush + abrasive belt). A detailed observation and analysis were carried out on the samples processed by the two machines to compare the differences in processing effects of various stations.

II. Detailed Analysis of Processing Effects of Each Station

(1) Processing Effects of the 2-Station (Abrasive Belt + Roller Brush) Configuration

The 2-station configuration, consisting of an abrasive belt station and a roller brush station, achieves basic deburring and chamfering of stainless steel components through collaborative operation.

- Abrasive Belt Station: As the first processing step, the abrasive belt station is mainly responsible for quickly removing obvious burrs and protrusions on the surface of stainless steel components. With strong grinding capability, the abrasive belt can efficiently eliminate large burrs generated during component processing, while conducting preliminary surface grinding to lay a foundation for subsequent processing at the roller brush station. After processing at the abrasive belt station, most large burrs on the stainless steel surface are removed, and the sharp edges are initially trimmed.

- Roller Brush Station: Following the abrasive belt station, the roller brush station performs further precision processing on the stainless steel components. The brush bristles possess moderate flexibility and grinding force, allowing them to reach gaps, corners and other areas that are inaccessible to the abrasive belt, removing residual fine burrs and polishing the chamfered edges. After processing at the roller brush station, the surface of the stainless steel components becomes relatively smooth, and the chamfered edges are more rounded, though there remains room for improvement in surface fineness and glossiness.

Overall, stainless steel components processed by the 2-station (abrasive belt + roller brush) configuration can meet basic deburring and chamfering requirements, with no visible burrs on the surface and rounded edges. They are suitable for applications where low surface precision requirements are in place.

(2) Processing Effects of the 3-Station (Abrasive Belt + Roller Brush + Abrasive Belt) Configuration

Based on the 2-station setup, the 3-station configuration adds an extra abrasive belt station, forming a processing flow of abrasive belt rough grinding → roller brush precision finishing → abrasive belt fine grinding. This upgrades both processing precision and surface quality to a higher level.

- First Abrasive Belt Station (Rough Grinding): Functioning similarly to the abrasive belt station in the 2-station configuration, it is mainly responsible for quickly removing large burrs and protrusions on the surface of stainless steel components, laying a solid foundation for subsequent processing. The abrasive belt used at this station features a relatively coarse grit size, delivering high grinding efficiency and enabling preliminary workpiece trimming in a short time.

- Roller Brush Station (Precision Finishing): Following the first abrasive belt station, the roller brush station performs meticulous processing on gaps, corners and other areas of stainless steel components. It eliminates residual fine burrs and conducts initial rounding treatment on chamfered edges, ensuring no burrs remain on any part of the workpiece.

- Second Abrasive Belt Station (Fine Grinding): This is the key additional process that distinguishes the 3-station configuration from the 2-station one. Equipped with a finer grit abrasive belt, this station is dedicated to precision grinding and polishing of the stainless steel surface after roller brush processing. Through the action of the fine abrasive belt, minor scratches and roughness on the component surface are further eliminated, resulting in a smoother and finer surface finish. Meanwhile, it enhances the surface gloss of the workpiece, endowing the stainless steel components with a superior visual appearance.

Overall, stainless steel components processed by the 3-station configuration not only achieve complete burr removal and uniform, rounded chamfers, but also feature a smooth, refined surface with high glossiness. They are well-suited for applications with strict requirements for surface quality and appearance.

III. Value of Adding an Extra Station

A comparison between workpieces processed by the 2-station and 3-station configurations shows that the added second abrasive belt station (fine grinding) delivers significant value enhancement, mainly reflected in the following aspects:

1. Superior Surface Quality

The added fine grinding station effectively eliminates minor surface scratches and roughness, greatly improving surface flatness and fineness. For stainless steel components requiring subsequent surface treatments such as painting or electroplating, the enhanced surface quality ensures stronger adhesion of coatings or plating layers, preventing peeling and boosting overall product quality.

2. Enhanced Aesthetic Appeal

Fine grinding treatment significantly increases the surface gloss of stainless steel components, showcasing a more attractive metallic texture. In applications with high aesthetic standards, such as medical devices, food machinery and decorative products, components processed by the 3-station configuration are better positioned to meet customer aesthetic needs and enhance product market competitiveness.

3. Stabler Product Performance

A smoother and finer surface reduces friction resistance during component operation, minimizing wear and extending product service life. Additionally, a surface free of fine burrs and scratches resists the adhesion of dirt and impurities, facilitating easier cleaning and maintenance and improving user experience.

4. Wider Application Scope

Components processed by the 2-station configuration are suitable for scenarios with moderate surface quality requirements. In contrast, the superior surface quality and aesthetic finish of 3-station processed components enable their application in high-end fields with strict precision and appearance standards, providing customers with more processing options to meet diverse needs at different levels.

IV. Recommendations for Station Selection

Based on the above effect comparison and value analysis, the following principles can be followed when selecting the station configuration of LANUSS deburring machines:

- If your products have low surface quality requirements, only need basic deburring and chamfering, and your budget is limited relatively, the 2-station (abrasive belt + roller brush) configuration offers a higher cost-performance ratio.

- If your products require high surface flatness, fineness and glossiness, or are applied in high-end fields, the 3-station (abrasive belt + roller brush + abrasive belt) configuration can better meet your needs and enhance product quality.

Through this explanation, we believe you have gained a clearer understanding of the processing effects and value of different station configurations of LANUSS deburring machines. In subsequent actual processing, you can select the station configuration rationally according to the specific requirements of your products, achieving a balance between processing effects and costs.