Main Processing Scope of the Equipment

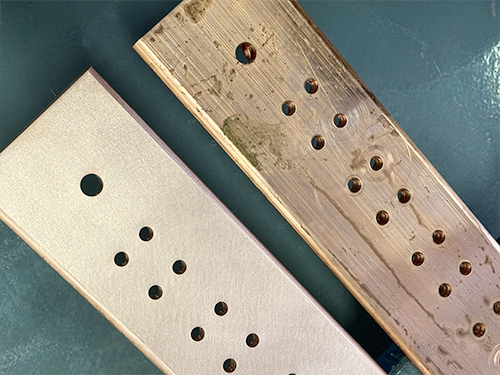

This equipment is a dry-type single-wide abrasive belt combined machine. It is mainly used for deburring, scratch removal, wire drawing, oxide scale removal, polishing and other processing treatments on the surface of metal plates.

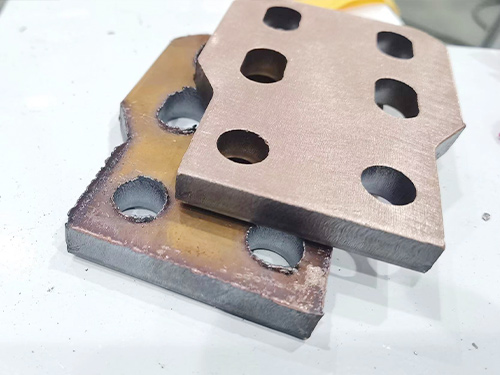

Processed Products: Stainless Steel, Carbon Steel, Aluminum Plates, Copper Plates, Various Non-Ferrous Metals, etc.

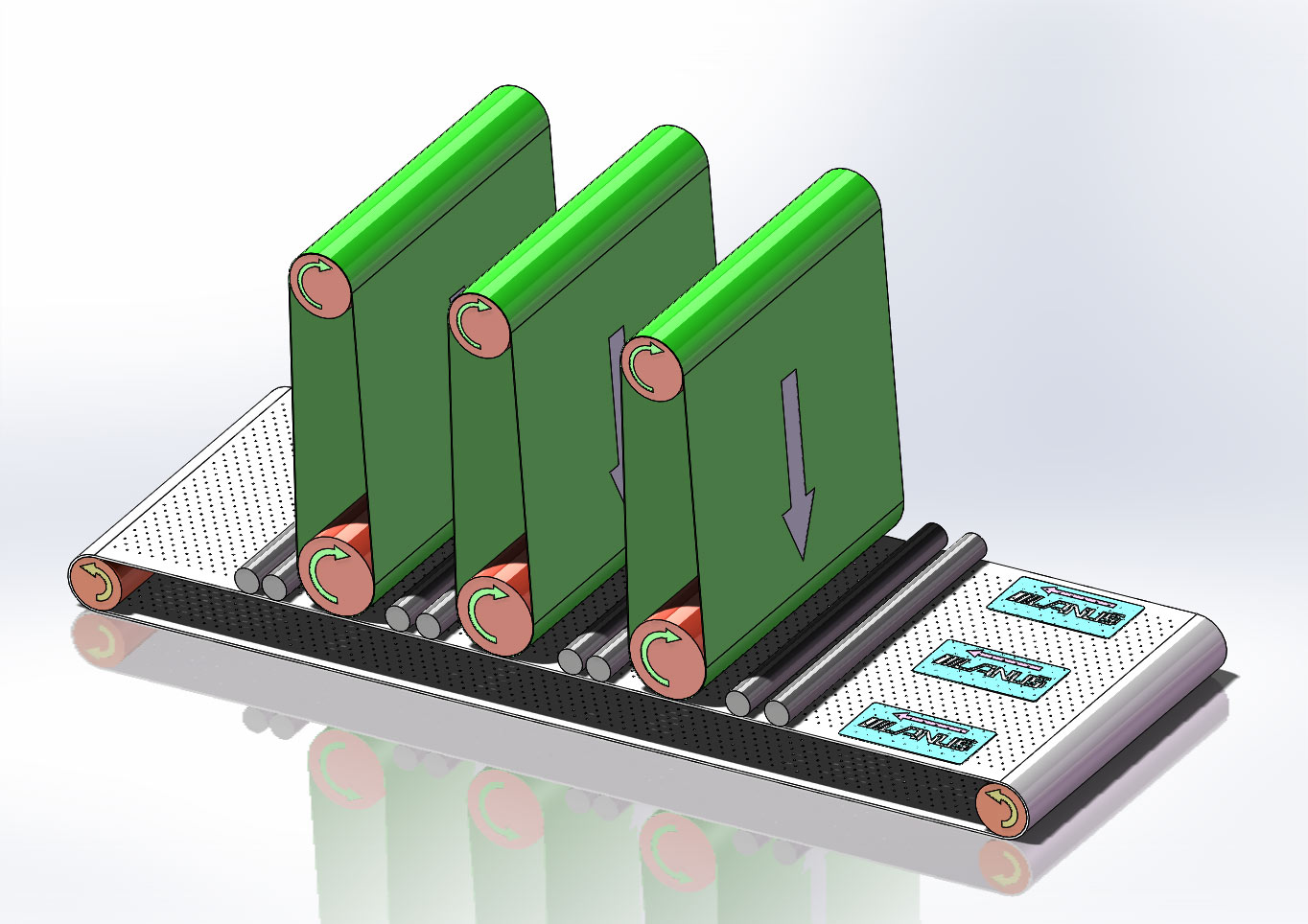

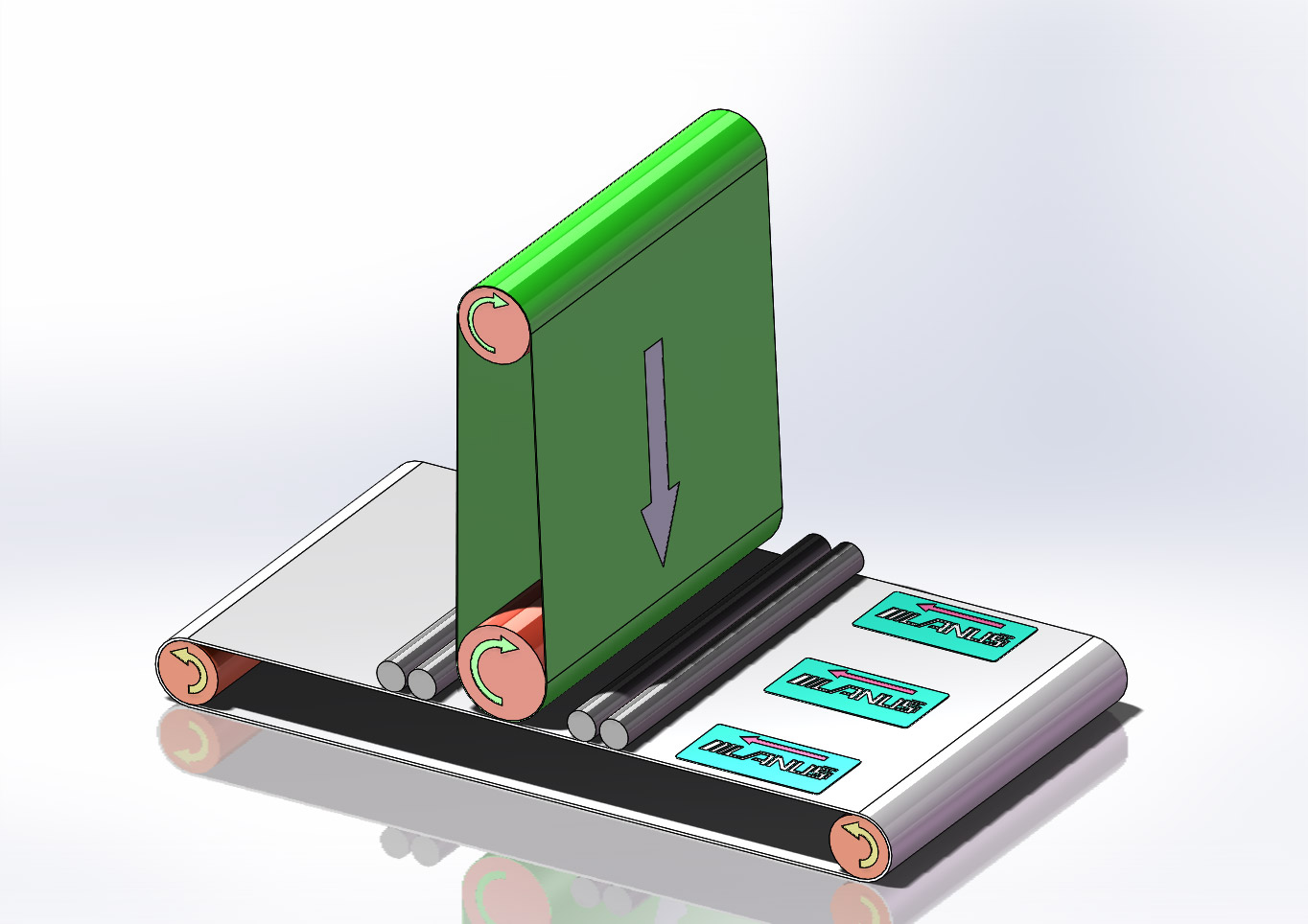

Working Principle of the Equipment

This equipment removes burrs, scratches, oxide scale defects, and performs polishing, wire drawing, and other surface treatments on workpieces through a set of high-speed rotating abrasive belt stations. With pass-through processing, it does not damage the dimensional accuracy of the workpieces.

Rubber rollers and conveyor belts pinch and feed the workpieces. For workpieces over 280mm, pass-through processing without fixtures is achievable; for special workpieces, supporting fixtures can be selected for fixed processing. The conveying system features variable-frequency stepless speed regulation.

Equipped with a wet dust collector, it reduces potential safety hazards and efficiently handles grinding dust. Through the high-pressure and high-flow fan at the top, the grinding dust is sucked into the dust removal chamber. The dust is settled in water via water spray, achieving environmentally friendly filtration and absorption of the dust, while clean air is discharged into the atmosphere.

To provide operators with a good working environment, recycle grinding metal powder, and achieve environmentally friendly production.